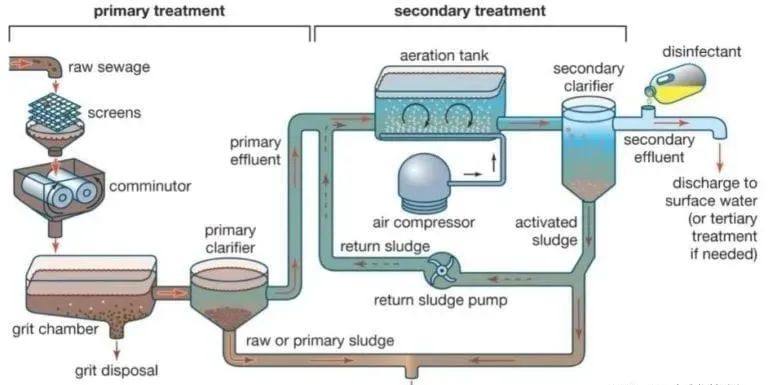

Traditional wastewater treatment involves three distinct steps: primary, secondary, and tertiary.

- Primary treatment removes solids through sedimentation or flotation.

- Secondary treatment involves the removal of organic matter through microbial decomposition.

- Tertiary treatment refers to any additional treatment required for wastewater reuse, recovery, or discharge into the environment. After primary treatment, wastewater enters a specially designed bioreactor where organic matter is broken down by microorganisms like bacteria, algae, or fungi, using either aerobic or anaerobic processes.

Factors Influencing Secondary Treatment Choices

The choice between aerobic and anaerobic processes depends on several factors, such as the wastewater’s characteristics, chemical and biological oxygen demand (COD and BOD), energy requirements, treatment time, capital investment, operating and maintenance costs, sludge production, space requirements, desired effluent quality, and microbial concentration.

The most effective configuration often combines both technologies. Aerobic treatment is typically used for low-strength wastewater (COD < 1000 mg/L), while anaerobic treatment is preferred for high organic loads (COD > 4000 mg/L).

Mass Flow in Aerobic and Anaerobic Processes

- Aerobic treatment utilizes oxygen and microbial biomass to assimilate organic matter and other pollutants (e.g., nitrogen and phosphorus) into carbon dioxide, water, and additional biomass.

- Anaerobic treatment, as the name suggests, decomposes organic impurities in the absence of oxygen, producing methane, carbon dioxide, and other biomass.

Mass flow controllers and meters are critical for achieving fast, accurate, and stable airflow and oxygen flow in aerobic processes. Similarly, flow meters are used to monitor methane and carbon dioxide flow rates during anaerobic processes.

Pros and Cons of Aerobic and Anaerobic Processes

Aerobic Treatment: Advantages

- Reduced odors (no production of hydrogen sulfide or methane).

- Superior nutrient removal, facilitating direct discharge into surface water or further disinfection.

Aerobic Treatment: Disadvantages

- Energy-intensive process due to oxygenation, resulting in higher energy consumption, utility, and maintenance costs.

- Undigested solids often precipitate as biosolids, requiring proper disposal, adding to utility and maintenance expenses.

Anaerobic Treatment: Advantages

- Biogas generated during anaerobic processes can be used as renewable energy (natural gas/methane).

- Produces significantly less sludge, which is easier to dewater and fully stabilized for disposal.

- Generally cheaper, simpler, and more flexible than most aerobic processes.

Anaerobic Treatment: Disadvantages

- Slower nutrient removal and the need for additional odor management due to hydrogen sulfide and methane production.

Combining Aerobic and Anaerobic Processes

Given the pros and cons of both methods, a combination of anaerobic and aerobic treatment is often employed for efficient wastewater management. Wastewater entering the aerobic reactor is typically pretreated in an anaerobic reactor to meet discharge standards in an energy-efficient and cost-effective manner.

Key Differences Between Aerobic and Anaerobic Processes

| Aspect | Aerobic Treatment | Anaerobic Treatment |

|---|---|---|

| Oxygen Requirement | Requires oxygen for microbial activity. | Operates in the absence of oxygen. |

| End Products | Produces carbon dioxide (CO₂), water (H₂O), and biomass. | Produces methane (CH₄), carbon dioxide (CO₂), and biomass. |

| Energy Requirements | High energy demand for aeration and oxygenation. | Low energy requirement; energy can be generated (biogas). |

| Sludge Production | Produces more sludge that requires disposal. | Produces less sludge, which is more stabilized. |

| Odor | Minimal odor as no hydrogen sulfide or methane is produced. | Potential for odor due to hydrogen sulfide and methane production. |

| Treatment Speed | Faster treatment process. | Slower treatment process. |

| Organic Load Handling | Suitable for low organic loads (COD < 1000 mg/L). | Suitable for high organic loads (COD > 4000 mg/L). |

| Nutrient Removal | Better at removing nutrients like nitrogen and phosphorus. | Limited nutrient removal capabilities. |

| Energy Recovery | No energy recovery. | Biogas (methane) can be recovered as renewable energy. |

| Cost | Higher operating and maintenance costs due to energy use. | Lower operating costs; simpler maintenance. |

| Common Applications | Used for municipal wastewater and low-strength industrial wastewater. | Used for high-strength industrial wastewater and organic-rich streams. |

Over the past few decades, the use of bioreactors in wastewater treatment processes has evolved from a cutting-edge new technology to a standard practice in sewage treatment. One key strategy for optimizing these systems is measuring input and/or output gases to effectively understand and control the process. The precise application of aerobic and anaerobic wastewater treatment processes depends on the unique factors of each facility. Accurate measurement of mass flow is critical for determining how best to utilize available tools to deliver the most optimal treatment solutions.