Under the dual pressure of industrial production and environmental protection, fluoride-containing wastewater treatment technology has attracted unprecedented attention. Traditional defluorination processes, such as chemical precipitation and flocculation, while solving some of the issues, often suffer from low efficiency, high costs, and complex operations.

Southwind offers an innovative solution with its new nanotechnology-based fluoride removal resin, HP3500, which provides precise treatment and stable compliance with standards.

HP3500 is an organic-inorganic nanohybrid adsorption material. It utilizes the Donna membrane effect, where surface groups on the polymer material pre-concentrate fluoride ions. These ions are then removed by fluoride-absorbing nanomaterials within the polymer, achieving high selectivity and adsorption precision for fluoride ions. The material’s rich nanopores and excellent hydraulic diffusion properties ensure rapid defluorination

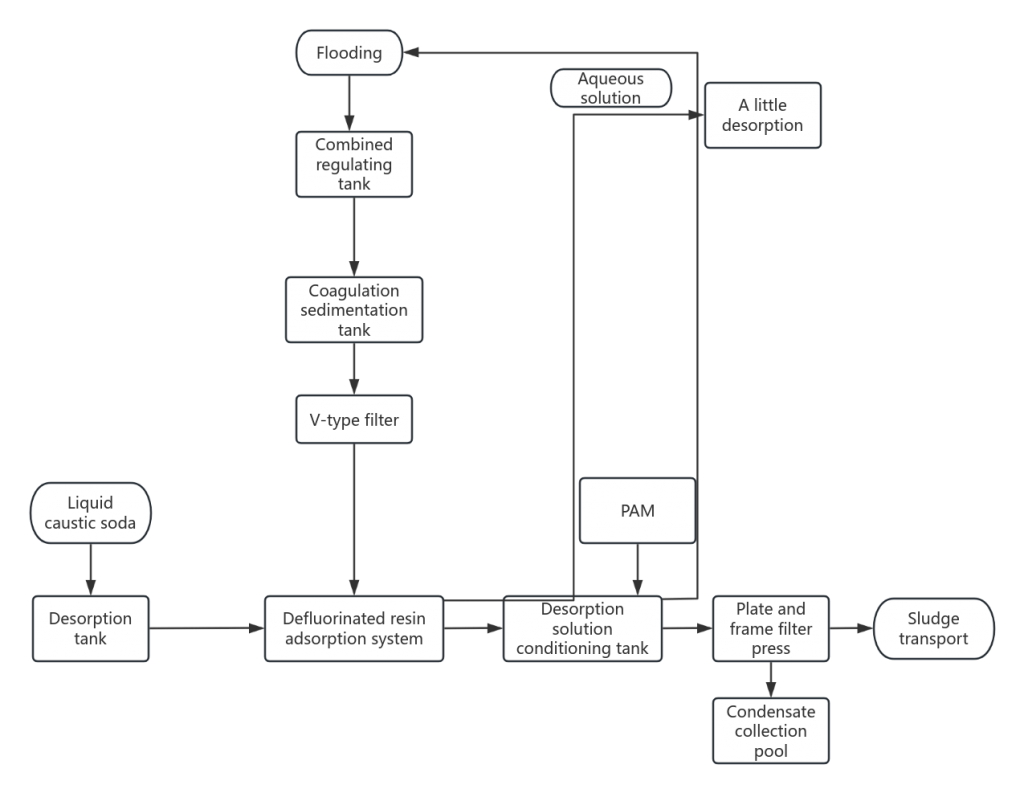

Fluoride-Containing Wastewater Treatment Process Flow

Fluoride-Containing Wastewater Treatment Process Flow

Southwind Core Process Advantages

Fully Automated Control:

HP3500 resin enables fully automated, unattended control, greatly reducing labor costs and operational complexity. This automation ensures consistency in the treatment process and minimizes the need for constant manual intervention.

Low Operational Costs:

The desorption solution used for regeneration can be reused multiple times, significantly lowering operational costs. This recyclability of the desorption solution contributes to overall cost efficiency.

High Adsorption Capacity:

Due to its use of nanomaterial-based resin particles with large pore structures, the HP3500 resin has an excellent surface area, which results in a high adsorption capacity. This makes it highly efficient in removing fluoride ions from wastewater.

Stable Treatment Effect:

The HP3500 resin ensures that fluoride ions are removed to very low concentrations, maintaining consistent and stable treatment performance over time. This stability is crucial for ensuring that the effluent meets environmental discharge standards or reuse requirements.

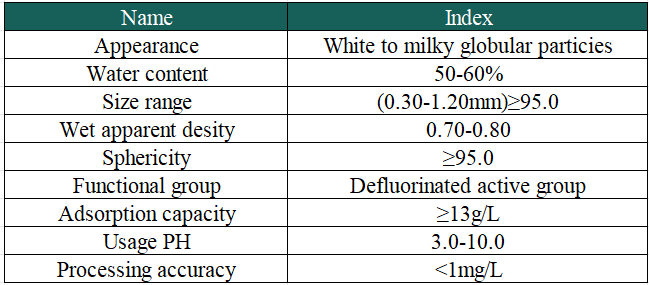

Fluoride Removal Resin Product Parameters

Fluoride Removal Resin Product Advantages

Ligand Exchange Efficiency:

The ligand exchange process offers better performance than traditional ion exchange, providing a higher exchange capacity for fluoride ions. This leads to more efficient removal and better overall fluoride treatment.

Higher Selectivity and Stable Performance:

The resin has excellent selectivity for fluoride ions, ensuring effective removal with stable treatment performance. The effluent quality remains consistent, and operational costs are kept low.

Simple Regeneration Process:

Desorption only requires a basic sodium hydroxide (liquid alkali) solution, making the regeneration process simple. Additionally, no aluminum (Al³⁺) ions are introduced as impurities, ensuring the treated water remains free from unwanted contaminants.

Strong Resistance to Interference:

The resin exhibits excellent resistance to interference from other ions such as calcium (Ca²⁺), magnesium (Mg²⁺), sulfate (SO₄²⁻), and chloride (Cl⁻), which ensures the selective removal of fluoride ions without being affected by these common wastewater components.

Purity of Desorption Wastewater:

The desorption wastewater contains only sodium fluoride (NaF) and sodium hydroxide (NaOH), allowing for simple and efficient treatment. The fluoride-rich waste can be further processed to produce relatively pure calcium fluoride (CaF₂) products, reducing environmental impact and improving resource recovery.

Applications in Multiple Industries

- Fluoride Removal in Lithium Battery Recycling Industry

In the lithium battery industry, particularly in the recycling and processing of used power lithium batteries, Southwind’s fluoride removal resin provides an eco-friendly solution. By using Southwind fluoride removal resin, fluoride ions in battery materials can be effectively removed, aiding in the recycling of lithium battery materials and creating economic value for clients. - Fluoride Removal in the Photovoltaic Industry

In the photovoltaic industry, Southwind’s fluoride removal resin plays a critical role. Fluoride-containing wastewater generated during the production process can be treated with Southwind’s resin to achieve deep fluoride removal, reducing fluoride concentrations to ≤1.0 mg/L. This solution resolves common issues such as limited adsorbent capacity and frequent regeneration needs. The HP3500 nano fluoride resin offers high selectivity for fluoride ions, providing customers with a high-quality, efficient fluoride removal solution. - Fluoride Removal in Coal Chemical Industry

The coal chemical industry generates high-concentration fluoride-containing wastewater, which has long been a difficult challenge to treat. Southwind’s fluoride removal resin uses selective adsorption to concentrate fluoride ions, significantly reducing fluoride concentrations in effluent to meet subsequent process requirements. Southwind’s high-performance adsorbents have a wide range of applications, high adsorption efficiency, and easy desorption regeneration. Fluoride removal from wastewater generally achieves or approaches discharge standards, with material adsorption rates exceeding 95%. - Fluoride Removal in Mine Water Industry

In the mine water treatment field, fluoride removal resin can effectively treat large volumes of wastewater, achieving fluoride concentrations of ≤1.0 mg/L. This addresses the limited adsorption capacity of many adsorbents. The application of Southwind’s fluoride removal resin not only improves the efficiency of mine water treatment but also reduces operational costs for enterprises. - Fluoride Removal in Semiconductor Industry

The growth of the semiconductor industry has introduced challenges in handling fluoride-containing wastewater. Fluoride removal resin shows high selectivity in semiconductor wastewater treatment, effectively removing fluoride ions and meeting increasingly strict discharge standards. The application of HP3500 nano fluoride resin offers clients a high-quality, efficient fluoride removal solution, ensuring the sustainable development of the semiconductor industry.

HP3500 Nano Fluoride Removal Resin

With its high selectivity, high adsorption capacity, low operating cost, and fully automated control, HP3500 nano fluoride removal resin is becoming a popular choice in the fluoride wastewater treatment field. It is not only suitable for various industrial scenarios such as fluorine-containing mineral washing wastewater, lithium battery leachates, photovoltaic, semiconductor, coal chemical, and mine water industries, but also effectively addresses fluoride removal needs in groundwater and drinking water in civil sectors. As environmental regulations tighten and industrial production continues to expand, HP3500 nano fluoride removal resin is undoubtedly poised to become the mainstream choice for fluoride removal processes in the future.