Key Technologies in the Adipic Acid Industry

Adipic acid is a vital organic chemical raw material widely used in the production of resins, food additives, plastics, and other industries, as well as in pharmaceuticals and fragrances. Currently, the nitric acid oxidation of alcohols and ketones is the most traditional and dominant process for adipic acid synthesis. In this process, adipic acid is produced by oxidizing alcohols and ketones with nitric acid in the presence of copper and vanadium catalysts.

One of the critical technologies in this production method is the recovery of copper and vanadium catalysts using resin. This step ensures the efficient reuse of catalysts, reduces material consumption, minimizes environmental pollution, and contributes to the economic efficiency of the process.

Adsorption and Separation Technology for Adipic Acid Catalyst Recovery

In the production of adipic acid, copper catalysts enhance the selectivity of cyclohexanol at high temperatures, while vanadium catalysts improve selectivity at low temperatures, suppressing and reducing the formation of byproducts. After the chemical reaction is completed, copper and vanadium are separated from the product-containing mother liquor in the presence of nitric acid to enable their recovery and reuse.

Given the high cost and significant annual consumption of copper and vanadium catalysts in the nitric acid oxidation process for adipic acid production, their loss has a considerable impact on production costs. To improve efficiency and reduce costs, ion exchange resin is used in the process to recover these catalysts effectively.

Southwind Technology’s Adipic Acid-Specific Resin

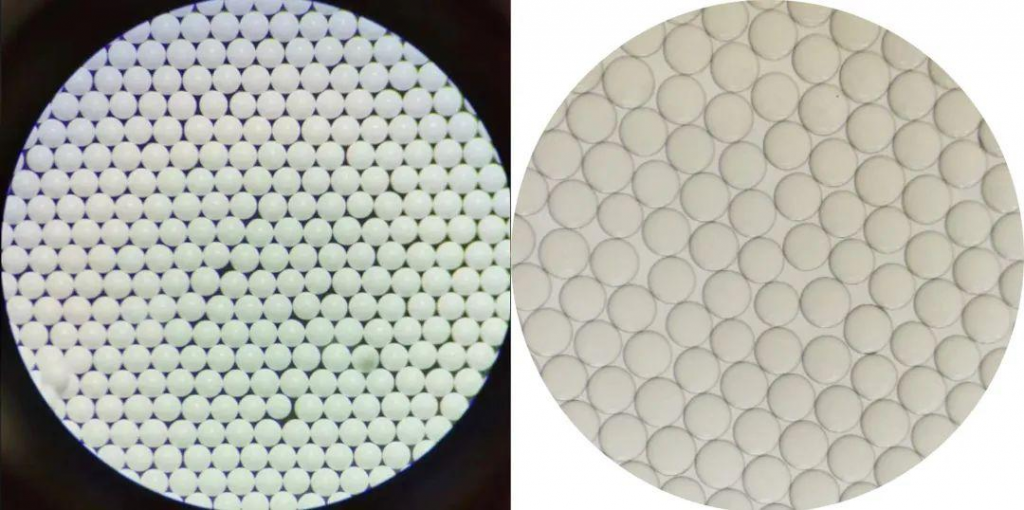

A common approach in the adipic acid industry is to pass the mother liquor through a resin bed, allowing the resin to adsorb copper and vanadium catalysts from the nitric acid-containing solution. The resin can then be regenerated for subsequent cycles. Southwind Technology has developed the LXC-501 ion exchange resin to meet the specific demands of the adipic acid production process. This resin exhibits excellent strength, high exchange capacity, strong adsorption for copper and vanadium catalysts, and superior resistance to nitric acid oxidation under conditions of elevated temperature and nitric acid concentration.

Advantages of Adipic Acid-Specific Resin

Southwind’s specialized resin demonstrates outstanding performance in industrial adipic acid units, with strong adsorption capacity for copper and vanadium, meeting operational requirements. Given the critical need to strictly control process parameters such as temperature and nitric acid concentration, optimizing these factors ensures the efficient recovery of copper and vanadium catalysts while reducing production costs.

In numerous case studies, the SW01 resin has demonstrated:

- High working exchange capacity.

- Excellent mechanical strength.

- Strong oxidation resistance.

These attributes make it an ideal choice for the catalyst recovery section in adipic acid production facilities, fulfilling stringent resin performance requirements.