Nuclear energy, as an efficient and clean energy source, plays a crucial role in human development and sustainability. Uranium, the primary fuel for nuclear reactors, is utilized for nuclear power generation. Its isotope, uranium-235 (U-235), undergoes fission within nuclear reactors to produce heat energy, which is subsequently converted to mechanical and then electrical energy. Due to the limited domestic uranium resources in China, the majority of uranium required for nuclear power plants must be imported.

The development of uranium extraction resins not only enhances national energy independence but also reduces reliance on imported energy, thereby bolstering energy security. Additionally, uranium extraction resins can recover uranium from nuclear wastewater, enabling resource recycling. These resins help reduce the demand for newly mined uranium resources, cut costs, and mitigate environmental impacts.

Characteristics and Importance of Uranium Recovery

Uranium typically exists in nature in the form of uranium ores, such as pitchblende, calcium uranium phosphates, and silicates. In these ores, uranium is generally found as oxides, phosphates, or silicates. Common uranium extraction methods include:

- Acidic Extraction: Using sulfuric acid to dissolve uranium from the ore.

- Alkaline Extraction: Employing sodium carbonate solutions to leach uranium into the liquid phase.

The leachate is then purified and processed using appropriate technologies to separate uranium and enhance its concentration. Among the available methods, adsorption technology is highly effective due to its:

- High Efficiency: Adsorption resins efficiently remove uranium from the leachate, concentrating it for further use.

- Simplicity: The process is straightforward and adaptable for various industrial scales.

- Cost-Effectiveness: Lower operational costs compared to alternative methods.

- Environmental Friendliness: Adsorption minimizes waste generation and avoids the use of harsh chemicals.

Southwind Uranium Extraction Resins

Southwind’s uranium extraction resins are specially designed for nuclear wastewater and leachate applications. They feature high selectivity, strong chemical stability, and an optimized pore structure, ensuring efficient uranium recovery even under complex conditions. These resins also allow:

- Efficient Resource Recycling: Extracted uranium can be reprocessed and reused in reactors, reducing dependence on newly mined uranium.

- Cost Savings: Recycling uranium lowers the operational costs associated with mining and procurement.

- Environmental Protection: By reducing mining activities, the ecological footprint of uranium extraction is minimized.

With the adoption of Southwind’s advanced uranium extraction resins, the nuclear power industry can achieve a balance between economic viability, environmental sustainability, and energy security. These innovations not only strengthen national energy strategies but also set a benchmark for eco-friendly uranium processing technologies.

Southwind has successfully developed three specialized uranium extraction resin products to cater to various application scenarios: HPN1053,HPN340,and HPN705

HPN1053 – Designed for uranium recovery from uranium ores.

HPN340 – Optimized for uranium recovery from diverse leachates.

HPN705 – Engineered for deep uranium removal in nuclear power plants.

These materials represent significant technological advancements and have demonstrated exceptional performance in practical applications.

KFN340 Resin: Advanced Adsorption and Stability

- Outstanding Adsorption Performance

- Rich in polymer-based nanoporous structures with uniform cross-linking.

- Exceptional hydraulic diffusion capabilities tailored to the properties of uranyl ions.

- Strong adsorption affinity for uranyl ions, high effective surface area, and superior adsorption capacity.

- High Chemical Stability

- Resistant to the effects of desorption alkalis on the resin surface.

- High mechanical strength and excellent abrasion resistance.

- Capable of enduring multiple regenerations using alkaline solutions without performance degradation.

Application Benefits

The KFN340 resin is optimized for efficient uranium extraction, ensuring high adsorption rates and durability. Its robust design and resistance to chemical and mechanical wear make it a reliable and cost-effective solution for extended operational cycles in uranium recovery applications.

Comprehensive Uranium Extraction Solution: Key Advantages

- Simplicity in Operation

- Streamlined process flow with integrated equipment design.

- Easy installation, operation, and management.

- Environmentally Friendly

- Reduces the use of harmful solvents, supporting sustainable development goals.

- Cost-Effective and Energy-Efficient

- High filler loading capacity requires less material usage.

- Low equipment investment and operational costs.

- Quality Improvement and Efficiency Boost

- Resin products exhibit high selectivity, enabling efficient adsorption of target substances.

- Safety and Reliability

- Maintains stability during separation processes without introducing external impurity ions.

- Industrial Applicability

- Suitable for large-scale production, meeting the demands of industrial applications.

Southwind Uranium Extraction Application Scenarios

1. Uranium Extraction from Uranium Ore

- Technology: The adsorption method for uranium extraction from ore is not constrained by the concentration of the separated substance.

- Advantages:

- Low cost

- High efficiency

- Environmentally friendly

- Simple to operate

- Prospects: This method demonstrates broad applicability and significant potential in the uranium extraction industry.

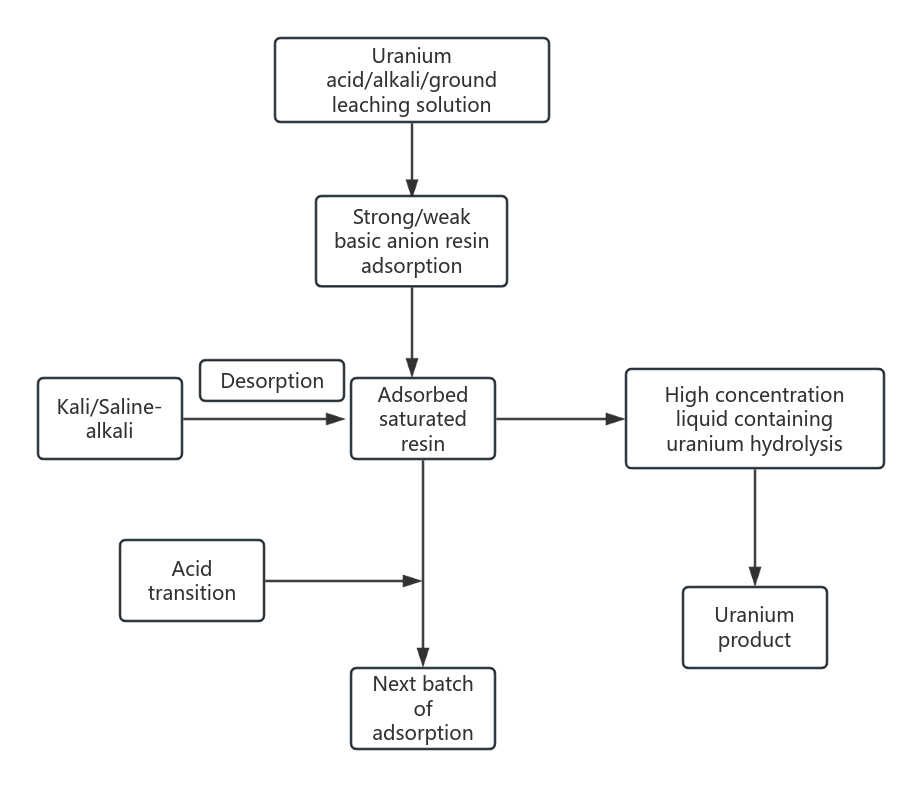

Uranium Ore Adsorption Extraction Process Flow

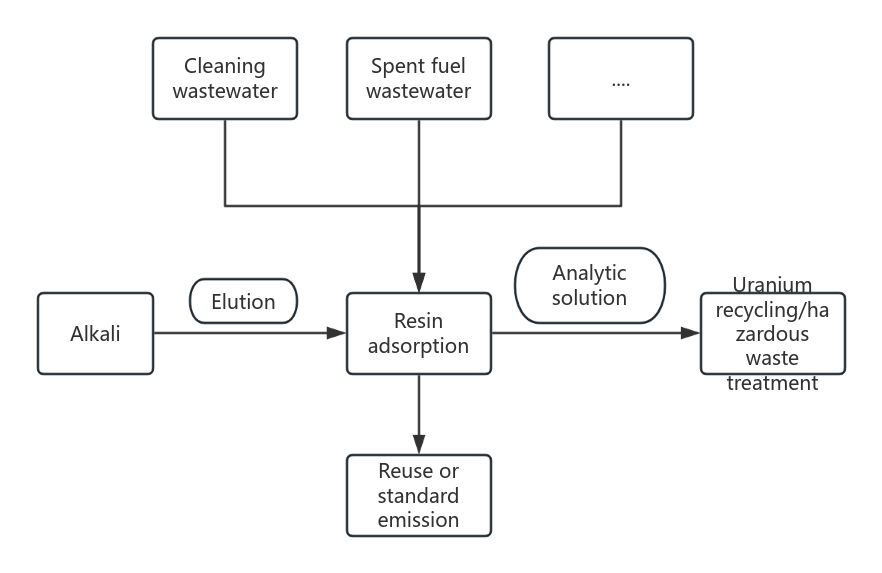

Deep Uranium Removal from Nuclear Power Plant Wastewater

The uranium concentration in wastewater from nuclear power plants, such as cleaning effluents and spent fuel handling, is relatively low. The adsorption method has become the ideal solution for uranium removal due to its:

- High Treatment Precision: Effectively removes trace amounts of uranium from wastewater.

- Long Adsorption Cycles: Offers prolonged operational efficiency without frequent regeneration.

- Low Operating Costs: Minimizes expenses while maintaining high performance.

- High Efficiency: Ensures reliable and sustainable uranium extraction with minimal resource consumption.

This method meets the demands of modern nuclear facilities for safety, environmental protection, and cost-effectiveness.

Deep Uranium Removal from Nuclear Power Plant Wastewater

Southwind’s Contribution to Sustainable Nuclear Energy Development

In addition to uranium extraction resins, Southwind has developed a series of nuclear-grade resin products aimed at efficiently removing or recovering radioactive substances. These resins significantly reduce the environmental pollution and damage caused by nuclear energy extraction and utilization. By improving energy use efficiency, Southwind provides robust support for the safe and green development of the nuclear industry.

The product range showcases Southwind’s commitment to advancing technologies that align with global sustainability goals while ensuring the responsible and efficient use of nuclear resources.