Nylon 6, also known as polyamide 6, is a high-molecular compound that is polymerized through a series of reactions, including hydrolytic ring-opening, addition polymerization, condensation, and equilibrium processes, using caprolactam as the monomer.

The purification process of Nylon 6 extraction water resin.

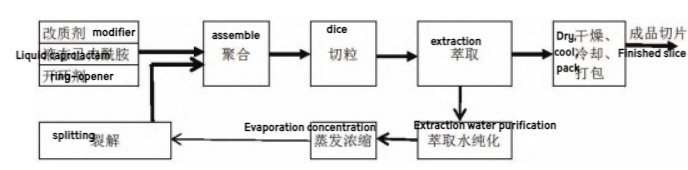

During the polymerization process of Nylon 6 chips using caprolactam as the raw material, the polymerization reaction includes both step-growth and reversible reactions, which results in a final reaction conversion rate of only around 90%. Consequently, approximately 10% of the polymer product consists of unreacted caprolactam monomers and oligomers. To achieve environmental protection and economic benefits, it is necessary to recycle these intermediate products. The original process involved directly concentrating the extraction water for reuse. However, since the extraction water contains a certain amount of inorganic impurities, this often leads to frequent clogging of pipes and equipment. Additionally, the inorganic impurities in the extraction water can affect the quality of the final product.

Ion Exchange Resin Purification Process

Since the extraction water contains a certain amount of inorganic impurities (metal ions, anions, silica, etc.), it is first purified using a high-temperature ion exchange resin device before evaporative concentration. The high-temperature extraction water flows evenly from the top of the cation exchange resin bed through a distributor. The cation exchange bed contains a certain amount of cation exchange resin. As the extraction water flows downward, the cations in the extraction water, such as Fe3+ and Na+, undergo ion exchange with H+ ions on the resin. After removing the cation impurities, the purified extraction water flows downward in the same manner and undergoes an ion exchange reaction with anion exchange resin to remove anionic impurities, such as SO42- and SiO32-. After removing both cationic and anionic impurities, the purified extraction water is pumped to a qualified extraction water storage tank for subsequent evaporation and concentration in the next unit.

LXG Series High-Temperature Resistant Cation and Anion Exchange Resin Applications

Southwind Technology has been dedicated to exploring and developing products in the chemical and chemical engineering fields, driving technological upgrades and innovations, and continually expanding into new application areas to achieve the refinement, separation, and purification of chemical products. For nylon 6 extraction water, which has a temperature of over 90°C, conventional ion exchange resins cannot operate effectively in such an environment for long periods. Therefore, Southwind has specially developed the LXG series of resins, which are resistant to temperatures up to 90°C, for the purification of nylon 6 extraction water. After purification by these resins, the extraction water can be reused, significantly alleviating issues such as pipeline blockages and improving the product quality of nylon 6.

High-Standard Cation and Anion Exchange Resins

Southwind Technology is currently the largest supplier in the resin industry and a publicly listed company. Leveraging its strong research and development capabilities, advanced production conditions, and a comprehensive quality control system, Southwind demonstrates industry-leading advancements in the production of cation and anion exchange resins, as reflected in the following aspects:

- Strict Raw Material Control: Combined with advanced automated production, the large-pore resin skeleton synthesis process features excellent pore structure, stable sulfur groups, and outstanding mechanical strength.

- Automated Production with Program Control: The automated production ensures stable performance between resin batches.

- High Exchange Capacity: The resin exhibits a high exchange capacity with more active H+ ions, offering strong exchange activity, high usage capacity, and extended service life, with a large cycle water production capacity.

- Excellent Temperature Resistance and Stability: The resin performs well under high temperatures and is capable of effectively handling organic contamination.