Challenges with Chlorinated Hydrocarbon VOCs

Chlorinated hydrocarbons such as dichloromethane, dichloroethane, and chloroform are commonly used as solvents or raw materials in industries like pharmaceuticals, pesticides, and fine chemicals. Due to their low boiling points, these substances are prone to volatilization during production, resulting in:

- Economic Loss: Material loss from volatilization.

- Environmental Pressure: Challenges in meeting exhaust treatment and emission standards.

Traditional treatment methods, such as activated carbon (or carbon fiber) adsorption, are not ideal due to their:

- Low Selectivity: Ineffective adsorption of chlorinated hydrocarbons.

- Variable Performance: Inconsistent removal and recovery rates.

- High Maintenance: Frequent replacement generating hazardous waste, increasing operational burdens.

Additionally, regenerative thermal oxidizers (RTOs), widely used for VOCs treatment, are limited in handling chlorinated hydrocarbons. Combustion of these compounds often produces corrosive hydrogen chloride gas and carcinogenic dioxins, restricting the application of RTOs to waste gases with chlorinated hydrocarbon concentrations below 200 mg/m³.

Innovative Resin Adsorption Technology by Southwind

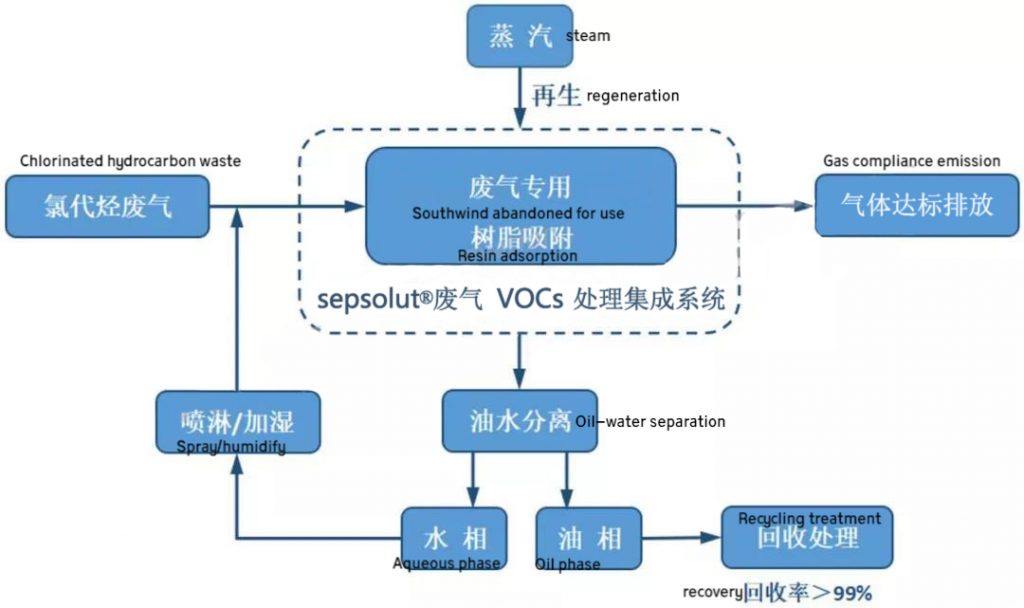

Southwind Technology introduces a groundbreaking solution: resin adsorption technology for chlorinated hydrocarbon VOCs. Using specially designed resin frameworks with high selectivity for chlorinated hydrocarbon molecules, combined with complex pore structures, Southwind’s system achieves:

- Efficient Adsorption: Intercepting and recovering chlorinated hydrocarbons from exhaust gases.

- Industrial Validation: Achieving removal and recovery rates exceeding 99% with consistent compliance for outlet emissions.

Advantages of Southwind’s VOCs Treatment Resin and Technology

High Efficiency and Precision:

- Removal and recovery rates >99%.

- Handles large volumes effectively.

Reduced Energy Consumption:

- Resin in spherical form with structural strength ensures lower system airflow resistance compared to activated carbon.

Durable and Cost-Effective:

- Minimal resin wear and long service life (>5 years under normal conditions).

- Annual replacement rate <10%.

- Operating costs significantly lower than activated carbon systems.

Operational Stability:

- Stable performance with low maintenance.

- Adaptability to fluctuations in airflow and concentration.

Sustainability:

- Recovered chlorinated hydrocarbons can be reused, further reducing costs and environmental impact.

Southwind’s innovative approach has been widely recognized for its effectiveness and practicality in addressing the challenges of chlorinated hydrocarbon VOC treatment. This technology provides industries with a reliable, efficient, and eco-friendly solution.

Schematic diagram of resin adsorption treatment technology for chlorinated hydrocarbon waste gas

Dichloroethane waste gas treatment project of a chemical enterprise

Dichloroethane waste gas treatment project of a chemical enterprise